Counterfeit consumables

A lot more trouble than they are worth

According to the International Chamber of Commerce (ICC), the value of global counterfeit goods is expected to exceed USD 1.7 trillion in 2015. And if you are thinking this is only a problem in the consumer marketplace, think again.

According to the International Chamber of Commerce (ICC), the value of global counterfeit goods is expected to exceed USD 1.7 trillion in 2015. And if you are thinking this is only a problem in the consumer marketplace, think again.

Counterfeiters are also targeting highly engineered, high-value industrial products, and our industry has not been immune to this growing threat. Plasma cutting consumables — nozzles, electrodes, swirl rings, etc. — are now being seen in all regions. Be alert, be smart, and don’t let counterfeit consumables compromise your work, or your safety.

Five reasons you should always buy genuine products through authorized distributors and avoid counterfeit products:

- Quality

Counterfeit suppliers have one thought in mind: a quick profit. They use the lowest cost materials and the cheapest, fastest production techniques; no stringent manufacturing processes, no quality control. Their products are inferior, inconsistent, and unreliable. - Performance

Plasma torches are precision devices requiring precision consumables. Any deviation from specified tolerances will impact overall performance. Result: poor or inconsistent cuts, reduced cutting speed, and significantly shorter consumable life. Or even a ruined or damaged torch. - Safety

The low quality metals used in counterfeit manufacturing may not be able to withstand the thermal demands of plasma cutting, putting equipment and, more importantly, operators at risk. - Aftersales support

If unknown parts have been used in a damaged torch or plasma system, it will make troubleshooting difficult, if not impossible. The use of unauthorized parts may also affect your warranty coverage. - Overall operating costs

Those “low cost” counterfeit consumables can be a lot more expensive than they look. For starters, they do not last as long as genuine parts — often only a fraction of the cutting life. Poor quality cuts may require costly rework, and valuable equipment could be irreparably damaged. There’s also downtime to consider, not to mention the risk to your business or your brand.

The only real bargain is real value

Counterfeits are usually very close copies of the genuine product, so it is easy enough to be misled, and think you are getting a good bargain. But this is one bargain that can be a major liability to your business.

The answer, of course, is to be alert for counterfeit scams, and to mistrust any consumable offer that sounds too good to be true. Be sure. Only purchase genuine Hypertherm consumables and only through an authorized distributor.

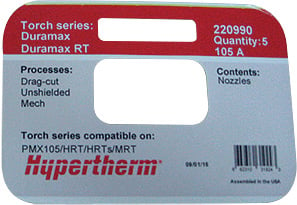

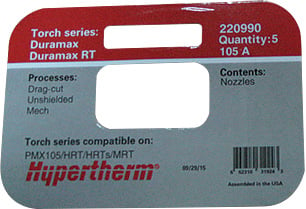

| Genuine | Counterfeit |

|  |

|  |

It’s not always easy to spot a counterfeit. Packaging is relatively easy to copy. Quality and performance are not.

How to make sure you are getting original consumables

To avoid being scammed by counterfeit consumables, here are a few things to watch out for:

- A claim of “genuine” consumables from an unauthorized distributor, an unknown agent, or off the internet

- Suspiciously low pricing for “genuine” consumables or software, or any offer that sounds too good to be true

- Discrepancies in the physical appearance of the label, packaging, or product, compared to that of the original consumable

- Poor or inconsistent consumable performance when compared to a genuine product — only 50% of usual service life, for example, or any abnormal signs of burning, metal deformation, etc.